PPC Landing Page Ink Pumps

Peristaltic Ink Pumps

“The Pump That Never Gets Wet!”

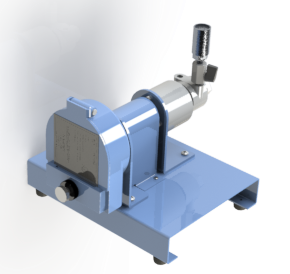

Randolph Austin ink pumps have a proven record in the printing industry. Available in various drive combinations and with several pump styles, Randolph Austin pumps are excellent choices when considering ink transfer for printing onto film with flexographic or rotogravure presses.

Peristaltic ink pumps offer many advantages over diaphragm pumps. Among those advantages are a softer pulsation and easier cleanup, that result less down time and maintenance.

Made from machined aluminum housings and stainless steel components, the Randolph Austin Peristaltic ink pumps are workhorses for this industry.

We stock various printing pump assemblies that are currently used in the print industry and will also work with your requirements to build a custom solution to your particular application.

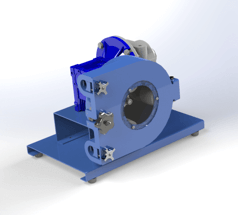

Model 750-455

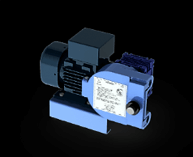

Models such as the 610-450, 620-450-5G, 750-455, 783-455, or 880-425 all use air motors that meet the EC directive 94/9EC (ATEX 100a) for use in zones 1 and 2 where explosive atmospheres of gas or dust are likely to occur.

Model 620-450-5G

Other configurations are also available such as variable speed DC motor drives, AC inverter duty drives, or pumps such as the 610-101 and 750-101 that utilize a mechanical speed reducer in line with a standard AC motor or with an explosion-proof motor as with the 610-201 and 750-201 models.

In addition to building the peristaltic pumps, Randolph Austin also extrudes our own tubing in a range of materials, and stocks most tubing sizes that are used for printing applications. Call or email our sales office for assistance.