How viscosity affects flow rates

Choose the Best Peristaltic Pump for the Job!

A frequent question regarding peristaltic pumps is how viscosity affects flow rate. The short answer is; as viscosity increases, flow rates decrease. That being said, there are various factors which need to be understood when considering a peristaltic pump for any application that requires pumping viscous fluids.

* The physical properties and geometry of the tubing selected have a direct effect on the flow rate capability of a peristaltic pump as it relates to a viscous fluid. After the tubing is compressed by the rollers it will rebound. The “rebound” is what creates the suction lift. Generally, the higher the tensile of the elastomer, like our Prothane II™ tubing, the greater its ability is to lift a viscous fluid. In terms of geometry, the larger the ratio of wall to inside diameter, the better the tubing is at rebounding from the constant flexing in the pump and therefore the better fluid delivery.

* As a general rule, the further the fluid is from the pump, the lower the flow rate will be. There are various reasons for these losses; laminar flow loss, the properties of the fluid itself (is it an adhesive or a lubricant), and the mass of the fluid to name a few. For applications where viscosity is a problem, it is recommended that the pump have a flooded suction or, at a minimum, be as close as possible to the fluid.

* As pump speed increases, the tubing has less time to rebound. For fluids at or near the specific gravity of water, there is very little effect of the increased speed, but when pumping a heavier fluid there is a point of diminishing returns where the flow per revolution will be reduced as the tubing does not have sufficient time for complete rebound inside the pump head.

750 series pump example:

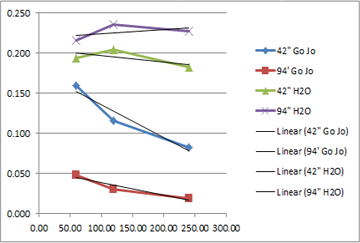

As a limited example of these effects the chart below illustrates the results of a flow test with a 750 series pump at three different speeds, and with two different intake lengths. We pumped GOJO™ soap and water. “Y” axis shows the pounds per revolution that the pump delivered. The water was used as a control for the test. As is evident from the chart the flow rate for water remained relatively constant at different speeds and different intake lengths. The results for the GOJO™ were very different with the pump flow decreasing as the distance from the intake source increases. The delivery rate in terms of pounds per revolution also decrease markedly as the intake length of the tubing increases.

GOJO™ is the trademark of GOJO Industries

Prothane II™ is the trademark of Randolph Austin Company